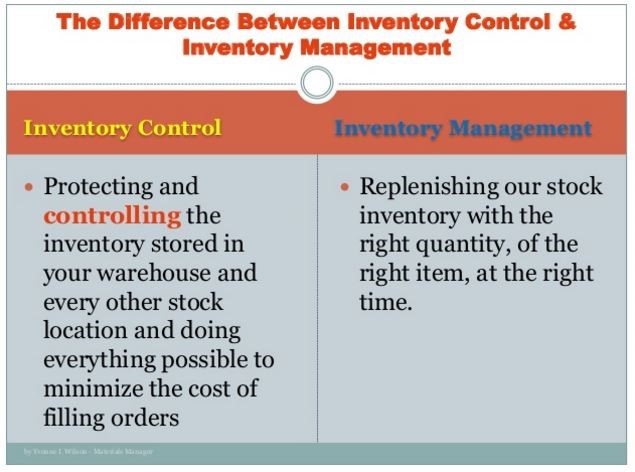

The terms "Inventory Management" and “Inventory Control” are the two sides of the same coin. But, there is a thin difference between them.

Inventory management is about getting the right thing from the right place at the right time.

The thing is a product, a component or an assembly stored in the warehouse.

Inventory control on other hand is a practical side of the inventory management and focusses on the time and cost.

An inefficient inventory control mechanism will waste all your inventory management efforts.

Mind it- your inventory contributes to 40 to 50 % of the entire cost of running your business.

It can throw you out of the business if not done the right way.

So review your inventory control practices, if your inventory is getting out of control.

As business owner, CEO or stock manager:

Wouldn’t you be happy, if you had no problems - stock-outs, excessive stocks or outdated stocks?

Wouldn’t you be more successful if you had had more cash in your hand than lock it up in you inventory?

Definitely Yes. You would be smiling.

But if you are not. Then definitely there are pain points in your inventory management and this is how they hurt you.

- If you overstock, it means you have excessive spare related costs. Add to it the cost of handling and your inventory overhead shoots up.

- If you under-stock, you expose your business to the risk of lost sales in a stock-out due sudden spike in the customer demand.

- If you have considerable obsolete inventory, you are investing your warehouse’s space, labor and time for nothing in return. You are losing money over outdated stocks and hurting profitability.

- If you have made a wrong inventory forecast because of wrong Business Intelligence (BI), improper market analysis, failure to understand changing customer preferences, then you end up with either an overstock or understock.

You know the consequences.

But, do not worry because your controlling inventory is no rocket science.

All you need is a good understanding of the workflow and a good judgment about of all your resources (inventory).

Here are the 5 secrets that will help you take the inventory control pain out of your business.

Feel the inventory pulse and plan accordingly

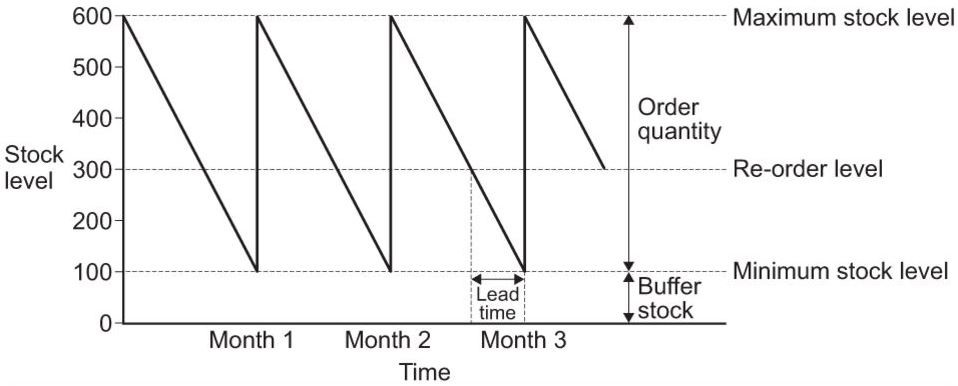

Break-down, operating inventory into three basic levels – minimum safe; re-ordering and excess.

It is easy to understand requirements of each level; plan and fulfill accordingly.

Insures the business unexpected problems order fulfillment and shipping delays, and distribution bottlenecks.

The end-result is production loss which translates into revenue loss.

To get the right feel of the inventory pulse feel of your business you have to understand the level mentioned below:

It is the lowest quantity that you should maintain for any material stocked in your warehouse.

The minimal stock level that buffers your business. If you maintain the level you prevent a production halt and shelves from going empty.

The minimal inventory depends upon the normal consumption rate and the normal delivery period.

Know the max consumption rate during peak production to prevent the inventory go down below this level.

Minimum Level = Re-ordering level — (Normal rate of consumption x Normal delivery period)

The re-ordering level is above the minimum level

At this point, you replenish the stock before the inventory goes below the minimal safe level.

It is also known as ‘ordering limit’ or ‘ordering point’ and it shields your inventory from the danger or sudden stock-out.

If you keep an eagle’s eye on ‘ordering limit’ of each of your stocks, you will never face the problem of stock-out.

Re-order level =Maximum Rate of consumption x maximum lead time.

Anything above this level, means you have unnecessarily blocked capital in excessive stocks. The added risks are more labor costs and stock deterioration.

If any stock reaches the maximum level, you can delay or postpone the next order fulfillment cycle till the same stock reaches its re-ordering limit.

Maximum Stock level = Reordering level + Reordering quantity — (Minimum Consumption x Minimum re-ordering period)

The average stock level is an average of the sum of minimum and maximum levels.

It lies between the in-between, below the reordering level.

Once your stock crosses the average level you can place purchase order with your vendor.

This strategy is effective in a warehouse where there are many fast-moving stocks and you do want to wait for stocks to fall to re-order level.

Average level =1/2 (Minimum stock level + Maximum stock level)

This may also be expressed by minimum level + 1/2 of Re-ordering Quantity.

This level is below the minimum level.

Put extra efforts to prevent your inventory go below, otherwise, stock-out is inevitable.

This level can be calculated with the help of the following formula:

Danger Level =Average rate of consumption x Emergency supply time.

Fine Tune the inventory level to your business’s requirement

It is logical for a business to have more goods or products, inventory than what’s required on hand. An ideal and safe practice.

But how much more? That is the key question.

If you overestimate, you overstock and if your underestimate you understock.

Both the scenarios are unwanted because they increase overheads and risk.

So what has to be done?

It is called Inventory fine tuning. Doing it right, creates the ideal inventory balance.

To achieve that you should:

- Know whether your inventory is right for the market or not

- Identify the fast moving and slow moving items in the inventory. Know their consumption rates.

- Spot the dormant or obsolete items.

The Action plan:

Keep your inventory is rightly aligned to your product and market. Otherwise, you will lose customers due to repeated, your "out-of-stock" banner at the shelves.

So get your inventory perfectly aligned your business goals.

The fast moving inventories drive your stock turnover which drives your business turnover. Put these items on a top priority in your order fulfillment list and pursue it vigorously round-the-clock. Your business will never face stock-out problems.

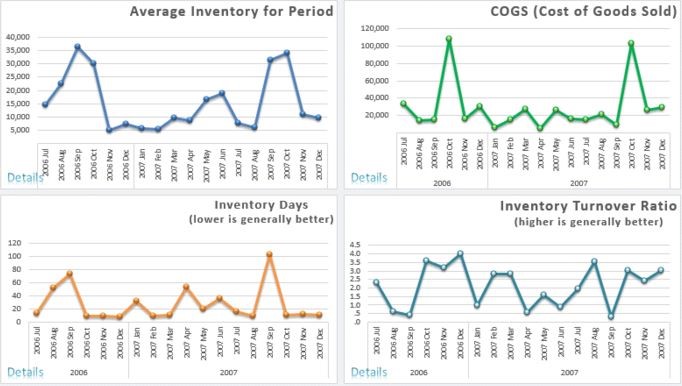

Note - The stock turnover rate is the rate at which the average inventory is completely replaced with the new one in one year.

Identify the obsolete inventories whose consumption has been dormant. Scrap them should either scrap them or gift them and get some tax benefits. The latter being the better option. Doing so you will allocate more space in the warehouse to useful inventories and save handling costs.

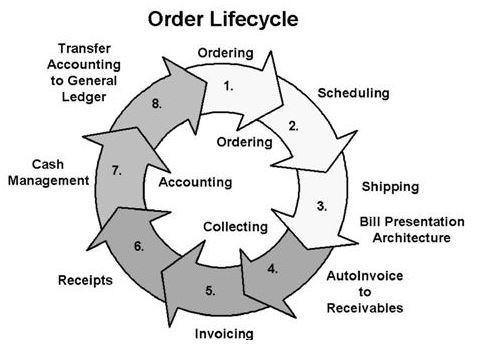

Plan and sync supply order cycles with your inventory

A smooth order fulfillment cycle is a requisite for the smooth working of your inventory.

Delay by suppliers and shippers will only dry up your inventory and make you struggle to fulfill your customer demands.

To mitigate such this risk, you should sync your purchase order cycle with your inventory.

First of all, predict the inventory’s demand. Then measure it up and come up with regular ordering quantities per item or product.

Next, select the vendors and negotiate, and create an order fulfillment cycle for each item. Streamline the vendor order management system.

If the certain quantity is sold for certain weeks or months at a steady rate. Then it is easy to schedule the replacements with equal regularity.

Plan accordingly and keep the door open to accommodate a sudden surge in consumption due seasonal demands.

Keep as many as possible vendors in your list of suppliers to mitigate the risks like:

- Seasonal inventory shortages at your vendor’ end that is affecting your inventory too and ultimately your business.

- Non-fulfillment of the purchase order by one or more of your vendors. You have others to fall on to.

- Your competitors are buying out components/products from your vendor and that is creating a shortage for you.

Get an insight of your projected inventory before you strike a long-term deal with your dependable suppliers.

You will be able to keep your inventory stocked at the optimum level, year-around.

Insure your business from complete stock-out, raw material shortage and price fluctuations.

Examine stocks periodically

You sales cycle are running smooth, the inbound and outbound shipping is on time and your business is growing. Everything seems fine. But…

Are your regularly feeling your inventory’s pulse?

If the answer is NO.

Then you better do.

The changing customer preferences drive the businesses and the competition within them.

You do not have time and money to sit out on the fast-turning - obsolete products like in Style Merchandise.

Today, innovation in the buzzword. You have to pay attention to your inventory and its alignment with your product.

Otherwise, you will soon find yourself sitting on outdated stocks.

Like in Style merchandise, where style fades fast, the efficient traders, markdown their fast-turning-obsolete inventory and sell them at discounted prices.

They convert the locked capital into cash, though at less gross value but are able to return in back to the business.

If that is the scenario in your inventory follow the path because technically speaking obsolete inventory should remove at any cost.

Inventory quantities must be checked, re-checked and reordered periodically. It is a labor-intensive and time-consuming exercise but a rewarding one. You get a clear picture of your inventory and are able to keep at an optimum level.